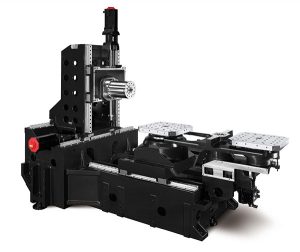

The latest addition to the Wele range of machining centres is the HMC500 horizontal spindle model, which offers positioning accuracy of ±0.005 mm in the X, Y and Z axes, and a repeatability of ±0.003 mm over the full working strokes of 640 mm in X, 610 mm in Y and 680 mm in Z. With 60 m/min rapid traverse rates in each axis, positioning times are reduced, contributing to shorter cycle times and higher levels of productivity.

Launched in the UK by 2D CNC Machinery, the 500 mm twin-pallet machine (optional 400 mm pallet size) has a maximum workpiece capacity within a cylinder diameter of 750 x 900 mm high with a full B axis. The B axis has 1600 Nm of torque and a positioning accuracy of 10 arc-secs (with a repeatability of 6 arc-secs). Also featured is a zero-point clamping system via four radial pre-tensioned tapers to ensure alignment. Index times are 1.5 seconds with a pallet interchange time of 7 seconds.

The built-in 22 kW, Big-Plus dual-contact spindle has a speed range between 40 and 15,000 rpm with up to 167 Nm of torque available through a low and high-range transmission. Spindle acceleration and deceleration is 3.3 seconds. In order to minimise any deformation caused through variable cutting forces or thermal effects, the spindle head is mounted between twin box-type gantry columns, while the cast-iron bed is supported via three-point levelling.

There is a 60-tool magazine, providing 3 seconds chip-to-chip time, which is capable of carrying tools up to 80 mm diameter (or 160 mm with adjacent pockets left empty). Maximum tool length is 400 mm. Control is via Fanuc 0i-MF.

For further information www.2dcnc.co.uk