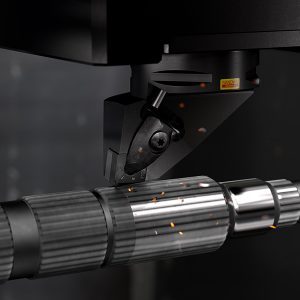

Haas Schleifmaschinen is expanding the range of possibilities of its Multigrind CA and CB grinding machines with a fully automated compact storage rack for up to 70 grinding wheels and 20 coolant protectors. A pre-finished linear axis system from Schunk is the key to flexible grinding wheel handling in minimum space.

Using the Schunk system, the shortest changeover time for an individual combination of wheel and protector within the storage rack (during processing time) is just 28 seconds, while the actual change on to the machine is carried out in a time of 10 seconds. Furthermore, milling cutters can be handled using the system, helping users to machine small contours or radii that cannot be reached with grinding wheels. As a safety door interface separates the machine from the storage rack (to protect it from oil mist), a shuttle table is used instead of the conventional machine tool changer.

The interfering contour-optimised axis system was designed by Schunk, and includes valve terminals, cable tracks and the connection to central lubrication. Two multi-tooth guided Schunk PGN-plus universal grippers take on the varied handling of the grinding wheels and coolant protectors. The gripping technology ensures that the tools are safely held in the event of a power failure.

With the aid of a Schunk swivel unit SRU-plus, the bottom gripper can be used both in combination with grinding wheel and coolant protector, and for removing and filling the individual grinding wheels and milling cutters.

In the Z-direction, a Schunk Delta 240C spindle axis is used, which is fitted with a rod lock, extendable spindle and shaft encoder.

For further information www.schunk.com