Aerospace engineering firm JJ Churchill has reduced its tooling costs by 5% with a 50% reduction in the number of machining operations on a specific critical part. This has been achieved with Blue Photon technology, which is marketed in the UK and Europe by NCMT.

The technology is being applied to an aerofoil blade component made from titanium aluminide, an extremely difficult material to fixture and machine. Blue Photon fixes the component to the tool with an adhesive, which cures under UV light, making it strong enough for rigorous machining techniques. The process is a replacement for encapsulation, providing reduced fixture complexity. Operation reduction is achieved by fixing on to a single face of the component, as opposed to potentially many faces.

Locating on a single face provides access to other faces, enabling several complex features to be machined at the same time. This capability delivers greater precision during machining, and ultimately reduces the amount of metal wasted/scrapped.

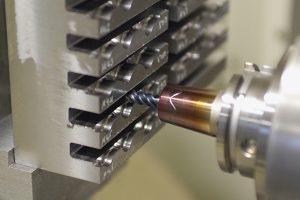

Once the blade root and tip have been machined (held using Blue Photon technology), the workpiece is transferred to a Starrag five-axis machining centre, in this case a 28 kW/18,000 rpm LX051. The workpiece is held in specifically-developed fixtures for the complete machining of the aerofoil from forged blanks that are, at most, 5 mm oversize.

The impact on JJ Churchill’s overall production is to increase capacity, which is essential as the company continues its growth trajectory, while also benefitting the environment. Using Blue Photon reduces the electricity required for the process.

For further information www.jjchurchill.com