A choice of effective clamping devices for tool and workpiece avoids expensive changeover times and helps to utilise the machine tool’s potential more effectively. With this in mind, the Precision Tool Association in the VDMA (German Engineering Federation), under the aegis of the METAV exhibition last month, hosted the 3rd Clamping Technology Forum.

Intelligent holding and clamping systems are becoming progressively more important in manufacturing operations, particularly as companies are increasingly having to deal with thin-walled and very small workpieces, as well as lightweight components. Here, intelligent clamping systems offer a huge potential for optimisation, although they also have “advantages when machining medium and small batch sizes with automated parts handling, and wherever comprehensive process monitoring is required”, says Henrik Schunk, managing partner of workholding specialist Schunk GmbH.

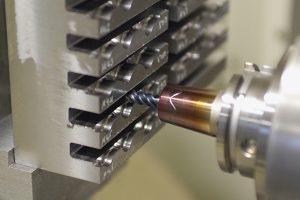

At Metav, Schunk gave a presentation on the importance of the toolholder in the production process. The company introduced an app with which a user can receive operating states of angle heads as raw data on his mobile terminal, enabling him or her to take countermeasures against production errors conveniently over a smartphone.

Angle heads are “very cost-efficient and flexible components designed to significantly expand the functionality of machine tools. Nowadays they are essential in an innovative metalcutting strategy,” explains Konrad Keck from Benz GmbH. Advantages and possible applications of magnetic and vacuum-based clamping techniques were also showcased at Metav.

Overall, experts presented numerous solutions, which thanks to the optimised deployment of clamping devices, can render the production process more efficient and cost effective.

For further information www.metav.com