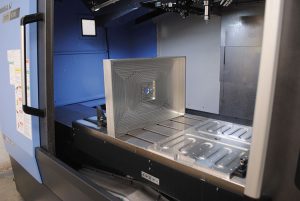

A UK machine tool supplier is benefitting from ‘girl power’ after its newest technical co-ordinator marked a major milestone. Chloe Reeve, 23, has just completed her 25th training course for Engineering Technology Group (ETG) clients, just four years after joining the business as an apprentice. She has played a key role in the firm’s roll-out of its Technical Academy Network and her latest course involved putting three employees from tool manufacturer Guhring through their paces on the new Hardinge Bridgeport XR760.

“2017 has been a great year for me and I’m really enjoying the new role, where I’m interacting a lot more with customers to make sure they receive the right technical advice and training on some of the new technology we are supplying,” she says. “During my own development, I’ve learned a variety of different CNC Programming languages, including Fanuc Turn and Mill, Siemens ShopTurn, Shop Mill and Heidenhain’s 530, 620 and 640 controls.”

For further information www.engtechgroup.com