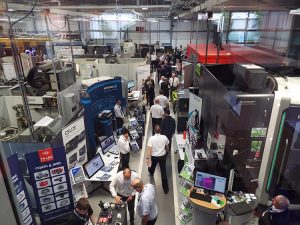

Seco Tools (UK) has reported that its recently-held ‘Inspiration through Innovation’ open house was a huge success with over 715 visitors attending the event over the two days. Now in its fourth year, highlights of Inspiration through Innovation included: 11 machining demonstrations; nine best-practice seminars led by industry experts; and over 50 technical partners showcasing their latest products, services and technology solutions.

“Our objective with Inspiration through Innovation has always been to create an inspiring and practical event that is truly customer-focused and demonstrates to visitors and partners alike that significant improvements in productivity, quality and performance can be achieved through collaboration and sharing best practice,” says Richard Jelfs, the company’s managing director.

For further information www.secotools.com