The University of Huddersfield’s £40m EPSRC Future Metrology Hub has joined Shanghai University to build a new Sino-UK smart metrology centre in China

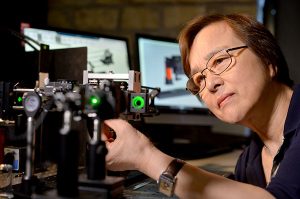

Senior delegates from Shanghai Jiao Tong University (SJTU), including its vice president professor Xi LiFeng, recently paid a fact-finding visit to the EPSRC Future Metrology Hub, located in the University of Huddersfield’s Centre for Precision Technologies, and met its director and professor of precision metrology, Dame Xiangqian (Jane) Jiang (pictured).

11.09.17

During the visit, the University of Huddersfield’s vice chancellor, professor Bob Cryan, signed a memorandum of understanding with professor Xi. The memorandum laid a grounding for future international co-operation in scientific research and exchange programmes for students and teachers to take place between the two institutions in the field of metrology. Also planned in the near future is a visit to SJTU by professor Cryan and the university’s pro-vice chancellor, international, professor Dave Taylor.

Professor Xi expressed his university’s keen interest in building a collaborative centre in Shanghai with the EPSRC Future Metrology Hub.

“The Future Metrology Hub is a leading research centre in metrology whose expertise is well recognised in academia and industry,” he said. “SJTU, with its strengths in engineering, is looking forward to complementing research interests and strengths with the University of Huddersfield’s Future Metrology Hub to build a world-class metrology centre in Shanghai that can serve the manufacturing industry in China and the UK.”

According to the 2018 Academic Ranking of World Universities, SJTU is 29th in the world for engineering, while also being one of China’s top research-oriented institutions, and the University of Huddersfield said it was honoured to welcome its visitors to the campus.

For further information https://research.hud.ac.uk