Walter Ewag UK has announced that its two-in-one Helitronic tool grinding and erosion concept has been extended to tools up to 420 mm long with diameters of 3 to 315 mm.

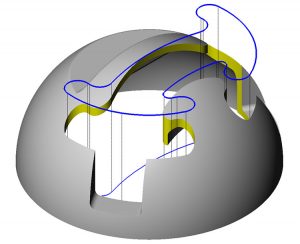

The new Walter Helitronic Vision Diamond 400L machine can grind and erode (in a single set-up) rotationally symmetrical precision tools such as end mills, reamers, stepped drill bits, shaped lathe tools, ball-nose tools and drills made from PCD, carbide, HSS, ceramic, cermet and CBN.

Walter’s two-in-one grinding/erosion process enables the machine to automatically switch between the production of PCD tools and carbide tools, and eroding and grinding, in one clamping cycle. Importantly, the Helitronic Vision Diamond 400L features Walter’s Fine Pulse Technology, which is the result of progressive improvements to the machine’s generator and its erosion software. With Fine Pulse Technology, surface finish is said to be like that of a polished (ground) tool.

The new Helitronic Vision Diamond 400L also features an inexpensive belt-driven spindle for the automatic switching of eroding and grinding wheel sets, complementing the options of dual and motor spindle versions.

Electrodes and grinding wheels up to 254 mm diameter can be accommodated, and up to 24 electrodes and/or grinding wheel sets can be used with the aid of optionally available wheel changers. A variety of different loader solutions are available for tool changing via a six-axis Fanuc robot.

For further information www.walter-machines.com