Laser-cutting specialist FC Laser has announced a record year with 30% growth in the past 12 months. The Derby-based company is doing so well that it will move to larger and more eco-friendly premises by the end of 2017 to help satisfy customer demand.

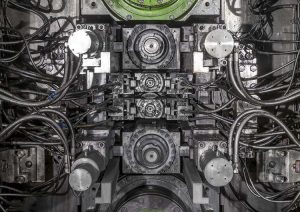

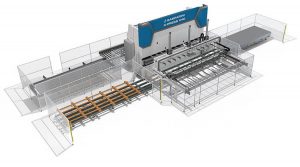

FC Laser’s new 20,000 sq ft factory has already received planning approval and the foundations will be laid this month. The company expects to receive the keys in December and is arranging for a prominent figure to open the new site. An open day is planned for March 2018 at which visitors will be able to see FC Laser’s suite of Bystronic laser centres, including a new 10 kW machine capable of cutting 30 mm thick materials. In other news, FC Laser has also been taking on new staff. These include account manager Brett Armitage, new business account manager Ellie Miller and apprentice internal sales engineer Will Krafts.

For further information www.fclaser.co.uk