According to Gasparini, mass production can now turn flexible thanks to the introduction of its latest smart press brake, which connects to the rest of the factory. The machine’s circuits, its frame, and its key components are populated with sensors in order to extract a wealth of data. This kind of forming line represents the very first press brake compliant with Industry 4.0, says the company.

The machine makes it possible to get detailed statistics about all production phases, as well as the cycle time needed to make a specific product. As a result, users can know actual costs, eliminate bottlenecks and monitor errors or other process-related problems. Another advantage of this network of sensors is the potential to detect problematic working conditions, and address them with preventive maintenance. Faults and machine stops can therefore be reduced, solving failures before they become production outages.

Sensors also allow the material being bent to be parameterised, keeping dimensional and strength variation under control. Furthermore, the machine will manage spring-back accurately and in real time, minimising the need for samples and tests.

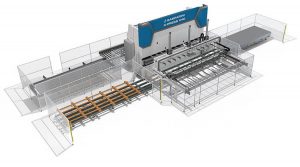

Another novel feature is integration with other elements of a ‘smart factory’. Different from machines of previous generations, this automated bending line can be interfaced with ERP, NAS, CAD and CAM systems. Users can perform remote uploads of bending programs and drawings. The press brake can be connected to laser cutters, automatic warehouses, welding lines and so on.

Gasparini will be showcasing its new automated bending line during an open house this week (12-13 May).

For further information www.gasparini.it