On Stand CM28 at Advanced Engineering 2017 (NEC, 1-2 November), visitors to the stand of Universal Robot (UR) distributor RARUK Automation will be able to see how humans and robots can work collaboratively.

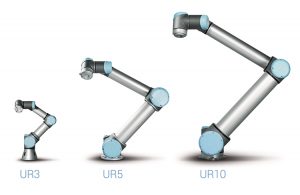

UR now offers three ‘cobot’ arms in its range, each categorised according to their payload limits. The smallest and most recent addition is the table-top UR3, which is virtually noiseless and compact with a footprint of just 118 mm. Total weight is only 11 kg but payload is 3 kg and, in common with other UR arms, has ±360° rotation on all wrist joints and infinite rotation on the end joint.

For further information www.rarodriguez.co.uk