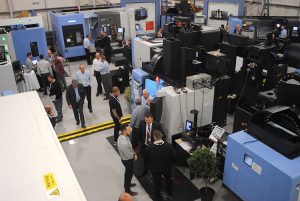

Describing itself as a one-stop-shop providing logistics, design, machining and part finishing for a high profile list of customers in the aerospace sector, Nasmyth Arden is focussed on attention to detail and driven to reducing process times through improved machine efficiency. This has seen the company invest in new machining capacity as well as seeing benefits from environmental improvements.

Specialising in the machining of billet material, on its 30, three-, four- and five-axis machining centres where up to 90% of the original material may be removed poses its own problems, in terms of airborne oil mist and other particulates. As a result, Nasmyth Arden is currently retrofitting every machine in its factory with oil mist extractor units from Matchmaker CNC.

“Any new machine we buy will be equipped with the Matchmaker extractor system and we have started to add them to our existing machines, starting with the five-axis machining centres,” says Nasmyth Arden’s production manager Alan Lucas. “The high-speed nature of these machines generates heat and, as a result, oil mist. When a cycle has finished the operator used to have to wait until this settled within the machine before opening the doors; this wait is eliminated with the addition of the extractor units.

“Matchmaker CNC have been working with us for many years providing service and breakdown cover on a wide range of machines, and when they introduced their range of extractors we could see the benefits they would bring and also that they provided a very cost-effective solution, allowing to quickly adapt them to all of our machines.”

Key to the success of the Matchmaker oil mist extractor is its patented conical filter. This requires much less maintenance than existing systems with the added benefit of a filter life of up to five years, depending on the application. The system is also highly efficient at particulate capture, removing up to 99.97% of particulates measuring 0. 3 µm. This efficiency is particularly beneficial in applications where dry smoke is created, such as when using neat oil metalworking fluids.

Designed to meet all European standards and surpassing the Euro F8 and F9 limits, the oil mist filters make use of a pre-filtering system using the principle of wind shear to separate oil, smoke, haze and toxic aerosols. The oil is then separated for recycling. Filter performance is monitored by a pressure gauge and carbon filtration module (active carbon module available as an option), which the company says can be replaced quickly and easily when required.

Machine utilisation is also important to Nasmyth Arden and here it was recognised that expensive machine time, particularly on its five-axis machines, was being used simply for roughing operations. Addressing this, Lucas turned again to Matchmaker CNC for a solution.

“We needed a machine with power and capacity to rough-out these billets of material; it needed to be capable and cost-effective, and Matchmaker’s solution of a Tongtai TMV1500A vertical machining centre fitted the bill. With its 10,000 rpm, BT40 spindle and 1525 mm X-axis, we could machine everything we needed to on it, using it for all of our pre-op work prior to transfer for finishing on the five-axis machines.”

The time savings being achieved by Nasmyth Arden are significant. For example, a typical aluminium chassis takes 23 hours to produce on the five-axis machine. This is now broken down to three hours roughing on the TongTai three-axis vertical machining centre, then finish machining taking 13 hours on the five-axis machining centre. Seven hours per component are saved, or roughly a day of production.

“The addition of the TongTai TMV1500A has given us higher metal removal capability, improved process times across the factory and greater overall flexibility as we can manage throughput much better by not tying up our high-value five-axis spindles,” says Lucas.

In addition to its 10,000 rpm, 11 kw spindle (8000 rpm standard), the Tongtai TMV1500A features rapid traverse of 18 m/min, feed rates of 10 m/min in all axes, a 24-position cam-type toolchanger, and door openings that allow ease of access for craning larger components on

to the 1600 by 762 mm table.

Casting components on the machine are made of high-quality cast iron. Equipped with huge boxways, the Tongtai TMV1500A is suitable for heavy-duty cutting, while the use of Finite Element Analysis (FEA) ensures static and dynamic rigidity. Chips are easy disposed by two chip augers and a flushing system.

While the benefits of health and safety in regard to oil mist extraction have been recognised for some time, the time savings that Nasmyth Arden are experiencing as a consequence of fitting these units to the company’s machines is also a major consideration in their application. Matchmaker CNC envisages a time when all machines will be fitted with systems such as this and, with the technology involved with the system, along with its price/performance ratio, the cost of retrofitting is no longer a real barrier to gaining these benefits.

For further information www.matchmakercnc.co.uk