Theorem Solutions has released the V21.1 version of its Visualize 3D CATIA V5 to JT solution. V21.1 supports CATIA V5-6R2015 to CATIA V5-6R2018, as well as all versions of JT, up to and including 10.0.

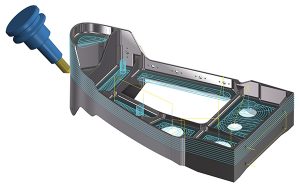

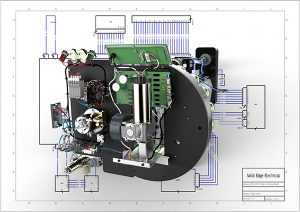

Visualize 3D products are aimed at creating visualisation data for users of digital mock-up, virtual reality or desktop applications, and for companies wanting to share JT data as part of a collaboration process. This unidirectional product can be licensed with Theorem’s JT to CATIA V5 product to create a bidirectional translator.

V21.1 enables CATIA V5 users to create a JT representation of their data and support the translation of assembly structure, geometry, attributes, 3D product manufacturing information (PMI) and metadata. The software can also be used as a data exchange format for popular CAD/CAM systems which support JT.

Visualize V21.1 also includes: a newly developed single JT configuration file that supports all translation requirements from (supported) CAD to JT, removing the requirement for multiple files; the ability to use standard CATIA V5 menus to select Theorem configurations created using the Theorem Configuration Manager or from within the Theorem Unified Interface; and the ability to export JT files directly from within CATIA V5 using the standard ‘File > Save As’ functionality, which helps to reduce the risk of error using familiar menus.

Theorem’s strategic partnerships with Dassault Systemes and Siemens ensure that there is parallel development between the latest releases of CATIA V5 and JT, and Theorem’s Visualize 3D products, allowing Theorem to continue to provide data solutions for CATIA V5 users wanting to create JT data.

For further information www.theorem.com