Poole-based subcontractor Alpha Precision Engineering has recently installed two Aberlink Xtreme CNC CMMs.

“Our first manual Aberlink CMM has proved to be easy to use, very accurate and ultra-reliable. Therefore, as the launch of Aberlink’s Xtreme CMMs coincided with a sharp upturn in our business, we placed an order for two of the new machines,” says quality manager Rob Allen. “As Aberlink’s Xtreme CMMs feature temperature compensation and are designed to operate both in inspection departments and on the shop floor, we have installed both of the new Xtreme CMMs in our production facility.

“Our new shop-floor Xtreme CMMs are now in regular use by our production personnel for in-process inspection checks and verifying first-off parts,” he continues. “Rather than lose time taking machined parts to our inspection department, fast and accurate CMM inspection results can now be achieved close to the point of manufacture. This quick feedback enables adjustments to be made when component sizes deviate from nominal conditions.

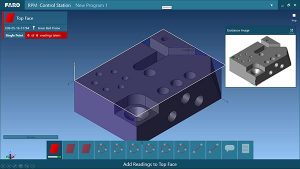

“Our quality staff also use our new Aberlink CMMs for final inspection routines and for other applications. The CNC nature of the new Xtreme CMMs enables them to be loaded with batches of machined components; the relevant program is then selected and, following the press of a button, a rapid, fully automated CNC measuring routine is started. In addition to storing the captured data related to individual measured features of each component in the batch, when required, we are able to generate detailed inspection reports for each part.”

For further information www.aberlink.com