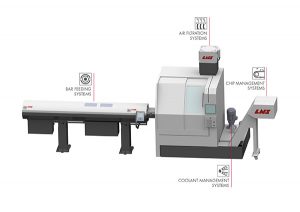

The CTX 2500|700 universal turning machine has been unveiled by DMG Mori. Designed for machining components up to 366 mm in diameter from billet, or 76 mm from bar, and to a maximum length of 705 mm, the machine is the first in the company’s range that allows users to turn grooves up to 12 mm wide in CK45 steel and drill holes to 80 mm diameter.

DMG Mori’s CTX 2500|700 combines the rigid machine bed and box guideway configuration of the NLX 2500|700, of which more than 10,000 have been sold, with the VDI turret and Siemens 840D Solutionline control from the CTX beta 800. DMG Mori’s proprietary app-based control and operation interface, CELOS, is included.

Precision and surface quality derive from the thermo-stability of the lathe, which has a spiral oil jacket around the spindle to control temperature and coolant recirculation through the cast bed. A linear scale with a standard resolution of 0.01 µm is fitted in the X axis for positional feedback. Furthermore, rapid traverse of 30 m/min in the linear axes ensures short idle times, while a Y axis may be specified for turn-milling work.

The TurnMaster 4000 rpm main spindle with 26 kW of power and 525 Nm torque (or optional 3500 rpm, 30 kW, 1194 Nm version) is opposed by an 11 kW, 7000 rpm, 70 Nm (or 32 kW, 5000 rpm, 360 Nm) counter spindle. A 6000 rpm, 32 Nm cooled-disc turret with VDI 40 interface is offered as standard, while an 85 Nm TorqueDrive and a 12,000 rpm SpeedDrive are available.

For further information www.dmgmori.com