A specialist in precision fabricated components for the earthmoving, construction and rail industries has marked its first venture into laser cutting by investing in a 6kW Trumpf TruLaser 3030 Fiber machine. The move has allowed Staffordshire-based Ecam Engineering to enter the market for different types of components, spurring growth of 20% in 2018, and introducing higher levels of cut quality and capacity.

“We quote for lots of different work here at Ecam, but the majority is for steel between 8 and 20mm thick,” states managing director Phil Arme. “We’ve been using plasma and oxy-gas profiling, but noticed more and more enquiries for a laser-cut finish. Not wanting to miss out on these opportunities, we did our due diligence and spoke with a number of laser profiling machine suppliers.”

Ecam shortlisted the most suitable candidates, visiting each one to perform material cutting trials.

“Some fibre laser machines are not the best at cutting steel up to 20mm thick, however, we were amazed by the trial at Trumpf,” states Arme. “Unlike at other places we visited, there was no tweaking involved, the machine just cut the material without any issues whatsoever. Moreover, the cut quality was by far the best we had seen.”

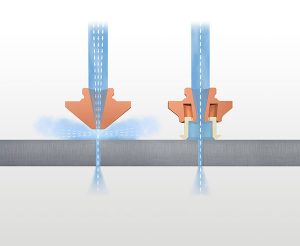

Duly installed, the TruLaser 3030 Fiber was supplied to Ecam Engineering with Trumpf’s CoolLine and BrightLine technologies. The former is proving to be particularly vital.CoolLine keeps temperatures constant by spraying a fine water mist around the point of cut. The evaporation of just 30ml of water per minute provides 1kW of cooling, and its use allows tighter parts nesting and narrower skeletons, resulting in better material utilisation.

For further information www.uk.trumpf.com