Esab has released its Cutmaster 60i hand-held air plasma-cutting system, a three-phase, 400 V unit that weighs 16.8 kg and provides a rated output of 7.6 kW at 50% duty cycle (at 60 A).

Cutmaster 60i produces a recommended cut of 16 mm, has a maximum sever thickness of 38 mm and, according to Esab, provides the fastest cutting speed (at any thickness) in its class.

Esab says that users will immediately notice the oversized, high-visibility LED display on the Cutmaster 60i, which communicates more information, more clearly, at a glance and from a distance. The display provides the necessary feedback to optimise parameter settings and cut quality. Cutmaster 60i also has a best-in-class ability to hold the arc for longer, which helps when cutting in awkward positions and when performing gouging operations.

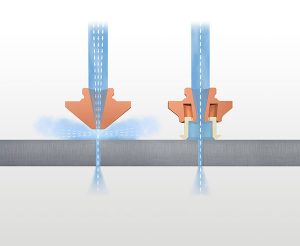

The system includes the new SL60QD 1Torch, which offers a quick disconnect feature for the selective replacement of either the torch handle assembly or torch leads at a lower cost than replacing both together (a necessity with one-piece torch/lead assemblies). Moreover, integral gas-optimiser technology helps ensure premium cut quality and performance by precisely regulating air pressure; although users can also adjust the gas pressure manually. When users set amperage, mode of operation, torch type, and add torch lengths to extend cutting reach by an additional 7.6, 15.2 or 22.9 m, the machine uses its colour display to provide recommended gas-pressure settings.

Low amperage especially benefits small shops and garage users as they might not have a large breaker like an industrial facility.

For further information www.esab.com