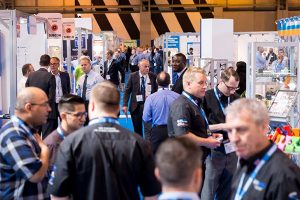

The 24th edition of MetalTech is set to take place on 23-26 May at Putra World Trade Centre in Kuala Lumpur, Malaysia.

More than 2000 companies from 33 countries will participate, showcasing hundreds of machine-tool systems and products revolving around this year’s theme of Industry 4.0 and smart manufacturing.

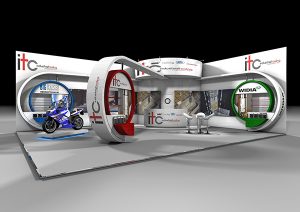

Like many other advanced countries, Malaysia’s manufacturing industry is undergoing a period of rapid transformation, implementing robotic assembly lines and computer controlled processes. As a result, a number of exhibitors are also showcasing complete assembly line systems, rather than individual machine tools. In addition, visitors will be treated to an opportunity to learn from industry heavyweights through the new live demonstration arena on the show floor, where ‘smartphone manufacturing processes’ will be the theme.

For further information www.metaltech.com.my