Around 10 years ago, Jan van Jaarsveld bought Clayton Precision Engineering and made the decision to concentrate on the aerospace industry. Today around 90% of the company’s business comes from this sector, including a long-term contract to supply parts and assemblies for the world’s largest manufacturer of ejector seats.

“The business is going from strength-to-strength,” he says. “Three years ago Clayton merged with another specialist engineering company, RA Fores Ltd. This merger dictated a move into a second unit, more than doubling our floor area, which we began filling with new Haas CNC equipment.

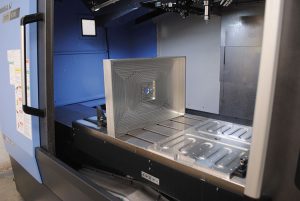

“We like the Haas machines; they’re quick, accurate and reliable and the back-up has been outstanding,” he adds. “Over the years, I’ve invested heavily in Haas; currently we have two Mini Mills, a VF-1 and seven VF-2SS Super Speed verticals. The most recent arrival is a five-axis VF-2SS with a trunnion table.”

The new five-axis machine is currently producing L168 aluminium components for ejector seats, reducing the number of operations from eight to just two. Furthermore, cycle times have been cut by 25%.

“It goes without saying that accuracy is vital when you’re dealing with parts that save lives,” says van Jaarsveld. “Our inspection department maintains quality control. All testing equipment is calibrated to national standards and we operate a TQM policy with recorded inspection undertaken at every stage of the job.”

Haas Automation’s VF-2SS has 762 x 406 x 508 mm travels, and comes as standard with a 12,000 rpm spindle and a 24+1 side-mount tool changer for tool changes that take less than 1.6 seconds tool-to-tool.

For further information www.haas.co.uk