Japanese ceramics specialist Kyocera presented a number of new products at the AMB trade fair in Stuttgart last month.

The debutants included the MEAS series for high-speed and high-performance aluminium machining, and the JCT (Jet Coolant Through) series of tool holders with a high-pressure coolant supply.

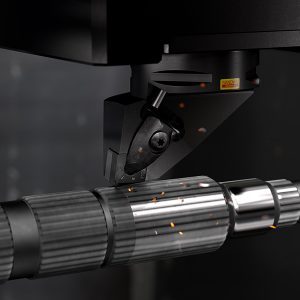

Milling cutters in the Kyocera MEAS series impress thanks to their long service lives and low cutting forces, says the company. The stable clamping system ensures the form-locking fit of the cutting plate in the plate seat. What’s more, a stable tool-holder design guarantees the durability and reliability of the cutter.

The JCT series of tool holders are optimised for a high-pressure coolant supply. For turning, there is the double clamp JCT variant, which allows a coolant supply from three directions, while for parting-off and external grooving, Kyocera has designed the KGD-JCT variation, which directs the coolant on to the rake and frank surfaces of the indexable insert. The KTN-JCT variation was developed for threading. In this variation, two cooling holes reduce the tendency for plate breakages and therefore facilitate an extension of service life.

In addition, the JCT series includes smaller tools with internal coolant supplies that can operate at a pressure of up to 200 bar. And again there are variations for turning, with screw clamping; these variations have two cooling holes that deliver coolant supply to the cutting edge surfaces of the indexable insert. For external grooving, there is the KGBF-JCT design, which directs the coolant towards the cutting edge of the insert. And for parting-off operations there is the KTKF-JCT variation, which directs the coolant towards the cutting surface from three directions.

For further information www.kyocera.com