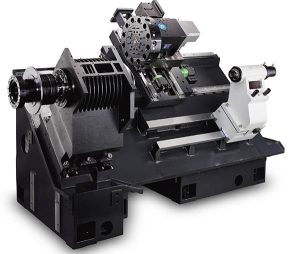

Now available in the UK and Ireland from official importer, sales distributor and sales agent, TDT Technology, is the Feeler range of FTC turning centres and slant-bed CNC turning centres. Aimed at machine shops tasked with heavy-duty machining operations, the machines are designed to offer a competitive cost-to-performance ratio.

The Feeler FTC range comprises three models, the FTC-10, FTC-20 and FTC-30. Between them, the machines cover a swing-over-bed of 520 to 600 mm diameter, a standard turning diameter of 180 to 310 mm, a maximum turning diameter of 240 to 450 mm, and a maximum turning length of 255 to 621 mm. All three feature a spindle equipped with precision, dual-direction, angular-contact thrust ball bearings, while a special heat-dissipation headstock design eliminates elevated temperatures from the spindle bearings, prolonging life and promoting reliability.

TDT says that machines in the Feeler FTC series of slant-bed CNC turning centres are designed for rigidity, efficiency and versatility. Kicking off the range is the FTC-300, which features a 6000 rpm spindle, 6” chuck and 52 mm diameter bar capacity. Moving up, the FTC-350, 350L, 350XL, 350LY (Y axis) and 350SLY (twin spindle) offer a 4500 rpm spindle, 8” chuck and 52 mm diameter bar capacity (66 mm option). All feature a 30° slant bed.

For an even more robust structure, the FTC-450 and 450MC (C axis and driven tools) provide a 45° slant bed, a maximum turning diameter of 450 mm and a maximum turning length of 650 mm. Finally, for the range’s highest power and rigidity, the FTC-640 and 640L again feature a 45° slant bed, which is matched with a 15” hydraulic chuck, 117.5 mm bar capacity, 22/26 kW spindle motor and A2-11 heavy-duty spindle.

For further information www.tdt-technology.co.uk