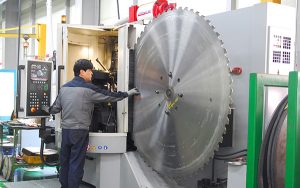

The DCM Company from Hwaseong, South Korea manufactures high-precision circular saw blades, as well as special purpose cutters and circular knives.

Products are supplied worldwide to all industries, such as steel pipe production, automotive manufacture, shipbuilding and aerospace. The company uses a dozen Vollmer machines for manufacturing its carbide-tipped circular saw blades, with some of its most recent recent acquisitions including the CHD, CHF and CHP models for single set-up processing. In combination with an ND handling system and appropriate loading carriage for automatic tipping, the machines are ready to use around the clock.

“At the end of the 1970s, I was teaching at a vocational school and noticed that our circular saw blades were always blunt when sawing metal cylinders, and often broke,” states An Youngmoon, managing director and founder of DCM. “This was my motivation to develop high-quality circular saw blades that permanently withstand the tough conditions of metal cutting.”

The idea soon led to the development of the first high speed steel circular saw blades manufactured by DCM. By the beginning of the 1990s, the company had developed carbide-tipped circular saw blades. From the outset, the company relied on sharpening machines from Vollmer.

“South Korea has developed into a high-end market for sharpening machines in the metals and composites sector, and the demand for service and user support is growing,” states Dr Stefan Brand, CEO of the Vollmer Group. “With the subsidiary we set up in Seoul in 2016, we can look after customers such as DCM even more intensively and competently than before.”

For further information www.vollmer-group.com