Matsuura Machinery has appointed three new engineers to its Spindle Department.

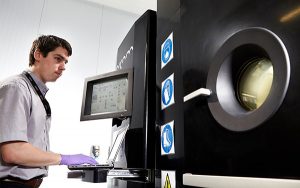

Said to be unique for any machine tool supplier in the UK, Matsuura’s Spindle Department, with its Class 1000 cleanroom based in Leicestershire, provides off-the-shelf service exchange spindles for Matsuura users all over the UK and Europe.

Paul Godfrey, spindle build engineer, is an experienced tool fitter and CNC machinist, having served in aerospace and power generation industry sectors. Joining him is Rhys Buxton, apprentice spindle build engineer, who prior to joining Matsuura undertook his apprenticeship at a precision machining company. Buxton is working towards his BTEC Level 3/NVQ3 in Engineering. The final addition is Sam Clegg, technical support engineer, who previously worked as a toolmaker and in machine tool sales.

For further information www.matsuura.co.uk