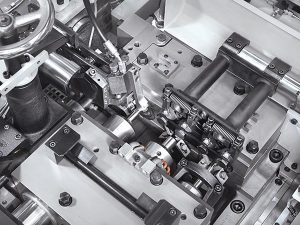

The Aachen Centre for Integrative Lightweight Production (AZL) at RWTH Aachen University is installing a new Engel injection moulding system.

Engel Deutschland GmbH – in co-operation with the Engel Centre for Lightweight Composite Technologies in Austria – will install the two-component injection moulding system with turning plate and 17,000 kN clamping force in 2019. This machine set-up is the basis for further developments in efficient inline combination technologies using different kinds of polymer performance materials.

AZL’s new Engel injection moulding system will enable innovative combinations of already established fibre-reinforced plastics (FRP) processes and the development of new individual processes. The focus is on increasing resource efficiency in lightweight production, with research addressing multi-material systems, continuous processes, process chains and self-optimising processes.

For further information www.azl-aachen-gmbh.de