Bridport-based sheet metal subcontractor, Ackerman Engineering, has installed an Xpert 150-tonne, 3.1 m press brake from Bystronic.

The move adds to the six Bystronic models already on site, one of which dates back to 2001 and is badged Edwards Pearson, which the Swiss manufacturer acquired in 2002.

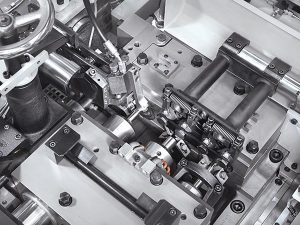

Managing director Graham Ackerman is particularly impressed with the latest Bystronic Xpert 150, for which he has bought a comprehensive suite of the manufacturer’s RF-A segmented tooling. He says it is twice as fast to set up compared with older style tooling, as the punch and die segments are automatically centred when loaded from the front and hydraulically clamped.

Moreover, the system is fully compatible with the Bystronic bending database in the machine control, and it is practically impossible to insert an incorrect tool due to laser beam recognition of its profile. Part quality is also improved, especially when bending long components, as there are no witness marks where the tool segments meet and there is no need for shimming.

Ackerman says: “Today we have 34 staff working at Bridport, including a fifth generation Ackerman, my son Edward. By the time he takes over the business, with our policy of constant reinvestment, we will have grown further. There is plenty of room for expansion on our current site. The purchase of highly productive production plant like the Bystronic machines will be key to our continued success.”

For further information www.bystronic.co.uk