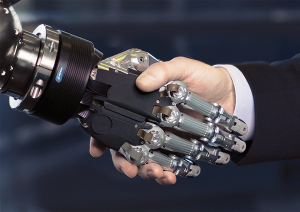

Schunk’s ‘Expert Days on Service Robotics’, now reaching its 10th anniversary, will this year take place from 28 February to 1 March under the theme ‘Smart Future with Cobots and Co-acts’.

Staged at Schunk’s headquarters in Lauffen/Neckar, Germany, the topic spectrum will range from cobot usage in logistics and distribution, through complex control and monitoring technology for robotic systems, to value creation with the help of data-supported methods such as machine learning, visual perception or speech recognition.

For further information www.expertdays.schunk.com