Hatebur has developed and tailored its HOTmatic AMP 20N, a machine that is specifically designed for the manufacturing of forged cam lobes.

With this machine, the company aims to improve the efficiency and productivity of suppliers in the automotive industry.

“Almost all of the world’s forged cam lobes are produced on Hatebur machines,” states Thomas Christoffel, CEO of Hatebur. “With the development of the HOTmatic AMP 20N, we are reacting to new trends in the industry. We want to make our customers even more productive and strengthen our market leadership.

“The trend is heading towards thinner cam lobes in order to support the lightweight construction of engines,” he continues. “That is why the R&D division of Hatebur has started early with fundamental research on cam lobes featuring a thickness of 8 mm instead of 12 mm. The thinner cam lobes impose higher demands on the forming machine – in particular with regard to the shearing quality, pressing force and part transfer.

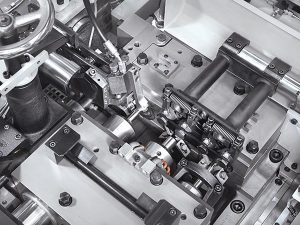

The HOTmatic AMP 20N offers a total press load of 1500 kN; the machine body has been reinforced to guarantee the necessary stability.

In three forming stations – and with a maximum of 200 strokes per minute – the AMP 20N produces cam lobes with an outer diameter of up to 48 mm out of raw parts with 24 to 217 g.

The up to 6 m long, almost 1200°C hot bars are brought exactly into position via four feeder rollers, powered by servo drives.

For further information www.hatebur.com