Established in 2010 by Dave Mawer and Mike Barratt, D&M Design & Fabrication has seen dramatic progression since the joint owners started running the business from the former’s bedroom and the latter’s garage.

At the time, neither thought that seven years later they would buy one of the most advanced fibre laser cutting centres on the market, a Bystronic 10 kW ByStar Fiber with automated sheet handling.

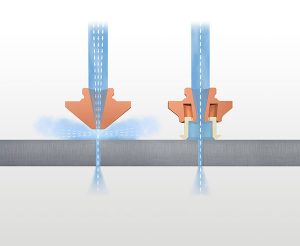

Installed at one of the firm’s factory units in Kirkby Malzeard, near Ripon, the machine is capable of processing 3 x 1.5 m sheet and employs the highest power fibre laser currently available on a cutting machine. According to Barratt, it is about 10 times faster at processing 10 mm thick material than D&M’s previous Bystronic 3.3 kW CO2 fibre laser machine bought five years earlier. A sheet can be completed typically in less than 40 minutes, rather than six hours.

“We were previously struggling to keep up with laser profiling our material, despite running the CO2 machine around the clock, six days a week,” says Barratt. “With the speed of fibre technology, we are easily processing more material per day in a single shift and now only work five days a week. The fibre machine stands idle for some of the time at present, as it finishes all the work going through the shop so quickly.”

Mawer adds: “With an eye to the future, we specified the machine with an inline ByTrans Extended handling system to automate the supply of material to the machine and the return of laser-cut sheets. We have proved the cell’s reliability during lights-out running a few times. It is not needed at the moment, but will be invaluable as volumes build in the future.”

For further information www.bystronic.co.uk