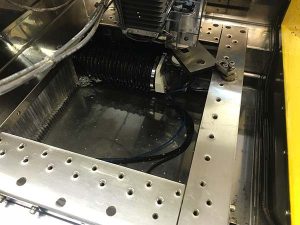

After the official launch at GF Machining Solutions’ International Solution Days in 2017, the AgieCharmilles CUT P 350 wire-cutting EDM solution was again in the spotlight at the EMO exhibition in Hanover at the end of last year.

Industries such as automotive and electronic components, faced with ever-shorter lead times, strive to increase their flexibility and production efficiency while executing their applications perfectly at the first attempt. The recently launched AgieCharmilles CUT P series represents a leap in terms of productivity with smarter machining, however difficult the machining conditions, says the company.

A significant step toward the increased connectivity of Industry 4.0, this range of solutions guarantees longer tooling life and reduces the need for manual operator interventions; reports GFMS. Users now experience 20% greater machining speed, accuracy down to 2 µm and benefit from having access to more than 600 dedicated technologies.

Visitors also experienced how the Mikron MILL S 400U five-axis electrode milling solution delivers stable precision over long machining periods and reduces, when not eliminating, manual finishing operations.

EMO visitors exploring the flow dedicated to the segment of electronic components also discovered complete solutions for achieving uncompromised accuracy over time. Coming together to address these challenges was the AgieCharmilles CUT 2000 X wire-cutting EDM machine with innovations that include automatic on-board quality control and increased cutting speed.

For further information www.gfms.com