Quality assurance is vital in the production of accurate, patient-specific implants, endoprostheses and surgical guides. Consequently, Baltic Orthoservice in Kaunas, Lithuania is now using a multi-sensor CMM with laser scanner in conjunction with a micro-CT (computed tomography) system, all supplied by Nikon Metrology.

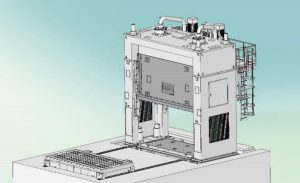

The Altera CMM with LC15Dx laser scanner supports the fast inspection of 3D printed implant surfaces and screw holes, while the XT H 225 CT guarantees internal structure quality and accurate geometrical correlation between CAD implant model and manufactured product.

Paulius Lukševičius, mechanical engineer, says: “3D printing is a complicated technology and there is a big variation in processing parameters, so predicting the quality and geometry of printed objects is quite a challenge. Patient-specific implants mean that the surgery must be ‘pre-planned’, virtually, so the implant can simply be put in place. To be able to execute the virtual plan, it is vital to be 100% sure that the implant geometry is exactly the same as the CAD model, and that the holes are machined to high accuracy.

“To fulfil these goals, we use a variety of metrology equipment,” he continues. “The CMM with laser scanner is irreplaceable when we need to perform fast checks after each manufacturing and post-processing stage, especially to check spherical surfaces, bearing surfaces and hole angles.”

Using this non-destructive, accurate metrology solution in its new quality control laboratory, together with a Nikon XT H 225 micro-CT system, helps

Baltic Orthoservice gain a deeper understanding of its products. In turn, this allows the company to “confidently produce bespoke implants and improve the quality of treatment for patients”.

For further information www.nikonmetrology.com