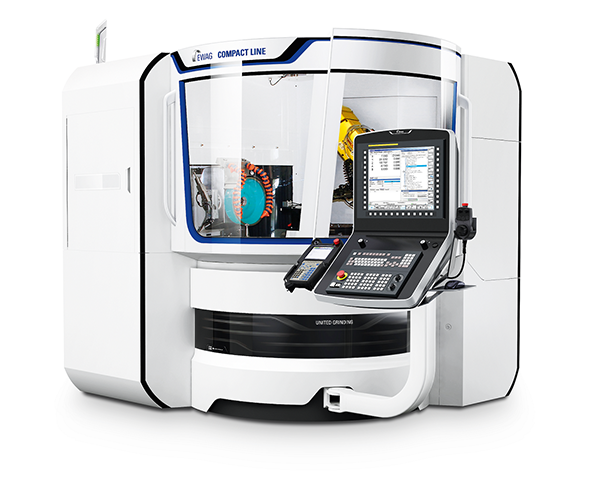

The new six-axis Ewag Compact Line tool grinder from Walter Ewag has been designed as a small-footprint, flexible solution for the grinding of inserts in tungsten carbide, cermet, ceramic, PCBN and PCD. Peripheral grinding is also included in the machine’s capabilities, alongside optimised kinematics and C-axis motion, which together ensure the application of protective chamfers on the inserts’ main cutting edges.

According to Ewag, machine downtime is minimised by the Compact Line’s short travel distances and integrated six-axis Fanuc robot that offers agile handling and a high degree of flexibility for loading complex inserts. A ‘three-in-one’ dressing unit offers wheel dressing, regeneration and form ‘crushing’ (for profiling diamond grinding wheels) in a single package.

Machine traverses in the X, Y and Z axes are 450, 180 and 150 mm respectively, while axis resolution is 0.0001 mm. The 5.5 kW grinding spindle produces 10,000 rpm.

Machine usability and effectiveness is also said to be guaranteed by the integrated ProGrind software, while the Fanuc control system enables all grinding routines to be programmed quickly and easily via its user-friendly touch-screen panel.

For further information www.walter-machines.com