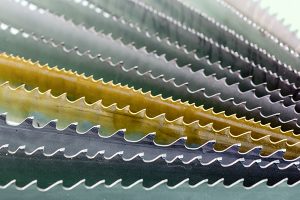

Master Abrasives has recently released a new range of Master Sawpro grinding wheels with a high-technology bond system specially engineered for the saw-sharpening industry.

The Sawpro range of wheels uses a resin bond developed for a cool-cutting action and longer life than alternative wheels. Sawpro wheels are specially designed for the manufacturing and re-sharpening of high-speed circular saws, and sharpening the tops and faces of carbide-tipped saw teeth.

Master’s Sawpro wheels are available in superabrasive and conventional abrasive grains, in all shapes and sizes. The popular industry specifications are 14F1 CBN wheels, which are suitable for Loroch machines, and diamond wheels, which suit most Vollmer machines for top and face grinding applications.

Ian Meredith, applications engineering manager, says: “Our team has developed the Sawpro range to deliver excellent performance with a cool cut, while offering great value for money. For the 14F1 CBN and diamond wheels, we will be holding stock of the most popular wheel sizes and grades.”

Master Abrasives launched the Sawpro line of grinding wheels at the GrindTec exhibition in Germany earlier this year. The key advantages of the high-technology bond system wheels were well-received by visiting engineers who work in the saw-sharpening industry.

“There was a lot of interest shown for Sawpro grinding wheels at the GrindTec event,” says Meredith. “Industry was missing a high-quality product for saw grinding that is also cost-effective, but the Master brand now fills that gap. We can offer full support with wheel selection and trials through our dedicated applications engineering team and overseas distributors to help manufacturers achieve their saw production and re-sharpening requirements.”

For further information www.master-abrasives.co.uk