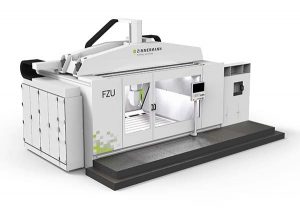

A portal, five-axis milling machine has been introduced by German machine-tool manufacturer Zimmermann at the lower end of its price range. Available in the UK and Ireland through Geo Kingsbury Machine Tools, the compact FZU is intended primarily for prototype, tool and mould making, as well as machining composite components such as airframes.

Of thermo-symmetrical and stable design, the machine is suitable for manufacturing workpieces from aluminium, plastics and model board. Unlike other machines in the Zimmermann range, the FZU is shipped in one piece so does not need to be assembled at the customer’s premises.

The working volume is available from a choice of X-axis travels of 2000, 4000 or 6000 mm, a 3000 mm Y axis, and either 1250 or 1500 mm movement in Z. Acceleration is 3 m/s2 to the maximum 60 m/min feed rate. Table loads of up to 10 tonnes can be accommodated.

The fourth and fifth CNC axes are provided by the newly developed VH10 spindle head, now the smallest in the manufacturer’s range. Of slender design, it provides minimal interference contours and high clamping force for stable milling.

A HSK-A63 spindle is standard, delivering 34 kW of power and 39 Nm of torque continuously, and offering a maximum speed of 24,000 rpm. The A axis swivels through 220°, while C-axis rotation is 300 or 360° for the smaller and larger Z-axis travels respectively. Resolution in both rotary axes is 0.0001°.

Control is provided by either a Heidenhain TNC 640 or Siemens Sinumerik 840D sl. Other options include spindle probing, tool measuring, and capacity for 40 or 60 tools in the magazine instead of the standard 20 tools.

For further information www.geokingsbury.com