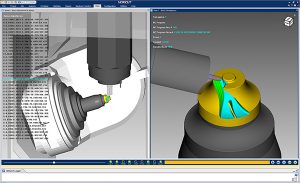

CGTech has announced the latest release of Vericut CNC simulation software, Version 8.2. With input from thousands of users worldwide, the focus of the latest iteration has been to provide features that improve simulation visibility, speed workflow, and streamline each user’s verification process.

Among the major upgrades are those relating to the user interface, force turning and additive manufacturing modules, to list but a few.

A modernised user interface now uses a right-mouse-button ribbon to put favourite Vericut functions just a click away, and provide convenient access to external applications that programmers find useful. The configurable head-up display (HUD) improves simulation monitoring and visibility by showing the NC program, or machining and cutting status information, overlaid on top of Vericut’s graphical views. HUD provides constant access to important details about the machining process, while keeping simulation views as large as possible for optimal viewing. Furthermore, NC program alert symbols and colours highlight errors and warnings found in NC programs, making it faster and easier to identify problem sources.

An additional enhancement relates to ‘Force’ a physics-based NC program optimisation module that CGTech says analyses and improves cutting conditions to achieve ideal chip thicknesses, while managing the cutting forces and spindle power required. Vericut 8.2 introduces ‘Force Turning’ to optimise lathe turning, and mill-turn operations, when combined with Force Milling. According to CGTech, Force Turning makes it easy to create NC programs for the optimal cutting of inside/outside diameters, shoulders, and in corners and tight spaces – without the worry of encountering excessive cutting forces or high spindle power demands.

For further information www.cgtech.com