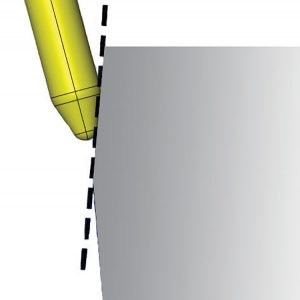

The new Eliminator series of end mills from Quickgrind is purpose-designed to increase metal removal rate (MRR) when performing five-axis machining operations. According to Quickgrind, the end mills incorporate a conical or tapered form that will deliver reductions in cycle time of up to 95%. This bold claim is substantiated by the ability of Eliminator to reduce tool-path distances while utilising the entire flute length to increase the step-down rate and subsequent MRR. Furthermore, the geometry of Eliminator reduces the potential for thermal deformation, dissipating heat from the cutting edges to extend tool life and improve surface finish.

From an application perspective, Eliminator tools are suited to semi-finish and finish-machining processes on a range of components, including aerospace turbine blades. The solid-carbide end mills are available uncoated or with Quickgrind’s Type D geometry, which features an MX coating for the machining of low- and medium-alloy steel, tool steel, cast iron and hardened steels. Alternatively, Type S end mills are XRed coated for the machining of high-temperature alloys such as Inconel, Hastelloy and titanium, as well as stainless steels.

Eliminator cutters can be used as a direct replacement for ball-nose and standard end mills. The tools are available as three- or four-flute cutters, which are offered in shank diameters of 6, 8, 10, 12 and 16 mm, which taper down to a ball nose diameter of 1, 2, 3 or 4 mm.

For further information www.quickgrind.com