Mapal used the EMO exhibition in Hanover last month as the launch pad for its new c-COM cloud-based data platform, as well as a host of new cutting tool lines. Tooling launches included the CPR500/510 replaceable-head reamer. Incorporating optimised cooling that offers an economic advantage when machining castings, this new arrival can extend tool life as its solid-carbide replaceable heads feature a purpose-designed CVD coating.

Complementing the latest reaming line was a complete new programme of ISO indexable inserts for boring steel, stainless steel and heat-resistant cast steel. Depending on prevailing conditions, such as material, machine stability, coolant and clamping, customers can choose between PVD- and CVD-coated cutting materials.

Elsewhere on the stand, Mapal revealed an extension to its three-edge Tritan-Drill range, which was launched last year. At EMO, the introduction of a specially adapted version for steel means that this material can be machined more cost-effectively compared with drills featuring two cutting edges.

Mapal also extended its programme of solid-carbide milling cutters for roughing applications with the new five-edge OptiMill-Uni-Wave. This full-slot mill makes it possible to produce groove depths up to 2xD, thanks largely to a highly ductile carbide substrate with a wear-resistant coating and special edge preparation.

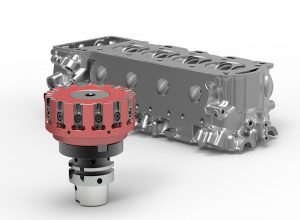

For face-milling operations, EMO saw the arrival of a new generation of milling tools for cutting depths up to 4 mm. With replaceable PCD milling cartridges, PowerMill-Blue is designed for machining aluminium in the automotive industry. Chip-guiding geometry has been optimised for the series, while the chip former is no longer integrated in the tool body but directly in the milling cassettes, ultimately resulting in better surface finishes.

For further information www.mapal.com