When Vetech Product Design & Development first opened its doors for business in 1994, the founders of the Buxton-based company exploited their expertise in the garden equipment sector to win business from Bosch. Providing design, consultancy, subcontract manufacture and mould and die tooling, the business has retained Bosch as a core customer while branching into the military, general subcontract, electronic sensor and plastic moulding sectors.

This diversification has been a welcome respite for a company that has noticed a dip in European business during the Brexit process. However, not a business to rest on its laurels, Vetech has applied its expertise to the motorsport sector, converting a Suzuki Hayabusa motorcycle engine for use in the Mark I to VII Mini produced from 1959 to 2000. It is here the expertise of CAM developer Open Mind Technologies has come to the fore.

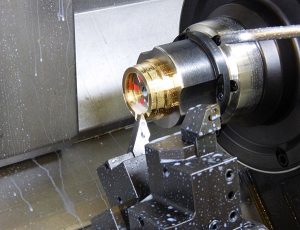

The subcontract company has a plant list that includes manual and CNC machining centres, injection mould machines and test facilities. Part of the acquisition trail includes a Hurco VMX42M and a VMX30Ti machining centre, with the larger VMX42M being retro-fitted with a fourth-axis rotary unit two years ago. Designing and manufacturing complex aluminium mould tools, military sensors and the Hayabusa engine, the previous CADCAM system was struggling to cope.

Commenting upon the situation prior to the arrival of Open Mind’s HyperMill CAM system, Vetech’s senior design engineer Andy Smith says: “Our longstanding CAD package had an integrated CAM system that we were using for all our machining tasks. One day we machined a mid-housing part for our Hayabusa engine and the VMX42M did a rapid traverse between two points, crashing into our fixtures and ruining the spindle. The result was weeks without the machine while we installed a costly new spindle. The lack of collision detection was a major cause for concern. We then programmed a gear selector barrel that proved almost impossible with our old package. We needed to change our CAM software and invited all the leading vendors to present their solutions.”

Being an experienced CADCAM designer and programmer, Smith has knowledge of all major CAM packages, coincidentally being one of the first UK engineers to be trained on HyperMill in the mid-1990s during previous employment at the Hyde Aerospace Group.

“Re-designing and re-manufacturing the Hayabusa 1300 cc engine to fit into a Mini meant we had to re-position the gearbox and add a reverse gear,” he explains. “I gave the gear selector barrel to all the leading CAM vendors and asked them to program it. Open Mind provided the most efficient and productive solution with an intuitive presentation that detailed the benefits of HyperMill over its competitors particularly well. Due to our previous experiences, collision prevention was a critical factor, something Open Mind certainly convinced us of. Furthermore, we needed to achieve faster programming times for our aluminium mould tools; HyperMill was once again streets ahead for mould tool programming.”

Re-engineering the Suzuki Hayabusa engine is undoubtedly an impressive feat of engineering that has genuine purpose. Once the power unit for the world’s fastest production road bike, the Hayabusa engine is a compact and powerful powertrain unit that can fit straight into the classic Mini while offering reliability despite the massive increase in performance. Such reliability is a rarity for any classic car.

The repackaged engine has seen Vetech engineers retain many of the power-producing components of the original Hayabusa. However, the conversion has seen the company add internal final drive gears and a differential, and re-position the gearbox beneath the engine, as well as introduce a fully integrated reverse gear. The engine has been turned back to front. Here, the repackaged engine/transmission has ‘universal’ engine mounts; bespoke mountings have been designed and manufactured for the mini but the engine mounting bosses provided permit easy integration into other vehicles such as the Fiat 500 or Lotus Elise.

Even the most powerful production Mini variant ever only developed 96 bhp, although the vast majority of Minis only offered around 65 bhp or less. An exceptionally highly tuned model can generate upwards of 120-130 bhp, but with very low reliability as a consequence. The Hayabusa engine has a power output of 197 bhp as standard and when re-packaged by Vetech, it weighs just 100 kg. This is a 32% engine weight reduction over the original unit. For those with an inclination for seemingly jet-propelled speed, Vetech also offers a super-charged 300 bhp unit.

During the development phase of the Hayabusa project, Vetech entered the 2016 ‘Fastest Mini in The World’ race at Brands Hatch. Starting in last position on the grid, the power to weight ratio propelled the car to second position in just three laps, only failing to win the race due to a water pump problem.

Programming the 11 core components of the re-modelled engine with HyperMill, Vetech has certainly benefitted from the CAM system, as Smith continues: “Programming and machining the Hayabusa project is not time-critical. What is important for us is the ability to program and machine complex parts with confidence in the collision avoidance system. Open Mind has completely modelled the work envelope into the CAM system with fixtures, machine spindle, tool holders and the Hurco fourth-axis rotary table all factored in. HyperMill stores a complete library of tool holders and tools, so we have 100% confidence in the anti-collision system. From a time-reduction standpoint, we programmed an aluminium mould tool for Hayabusa inlet and exhaust caps. With our previous system it took 20 hours to program and with HyperMill this same tool was completed in less than 10 hours.”

The upper housing of the engine consists of seven individual set-ups. With its previous CAM package, Vetech could not carry the stock model from one process to the next.

“Without the ability to carry the stock model forward to the next set-up, we would have to manually jog through the cycle on each set-up to minimise non-cutting times or run the program and wait for the tool path to finish ‘fresh-air’ cutting,“ says Smith. “The stock model feature within HyperMill eliminates fresh-air cutting and enables us to maximise machine utilisation at every set-up. This makes huge savings on complex parts with multiple set-ups.”

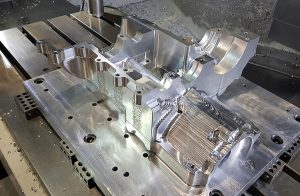

With over 60% of Vetech work consisting of aluminium mould tool production, the manufacturer programs the cores and cavities with HyperMill and simultaneously machines the two mating tool components overnight on the two Hurco machining centres.

To reduce lead-times, Vetech has invested in two HyperMIll seats, so one team member can program the core, while another programs the cavity. “We undertake prototype design, development and testing work on lawnmowers and there is often an urgency to respond to the customer. In most cases, we are expected to design, program and manufacture the mould tool [cavity and core] and then mould the plastic prototypes and conduct thermal and stress tests within 3-4 days. To achieve this, our programming and machining times have to be extremely efficient.”

For further information www.openmind-tech.com