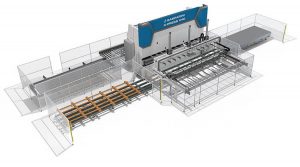

Bystronic has launched a press brake that can be moved around by fork lift truck. Despite a footprint of less than 3 sq m, the machine offers a bending capacity of 80 tonnes over 1.5 m.

Called Xpert 80, the press brake joins the smaller 40-tonne, 1 m Xpert 40 model. Both are able to boost productivity by avoiding the need to use a large, slower press brake to bend small components. Output can be increased further by relocating the machines next to a laser cutting cell, another press brake or other machine tool.

The Xpert 80 press brake can bend material up to 20 mm thick and may be equipped with multiple tools. ByMotion drive control, a Bystronic development, ensures that the machine’s upper beam and back gauges are accelerated quickly without compromising precision. Bending speeds of up to 25 mm/s are attained.

Ergonomic design features include drawers built into the side of the machine for housing bending tools and other equipment within easy reach of the operator. A height-adjustable folding table at the front of the machine can be used as a working surface or storage area. Power consumption is low due to the machine’s energy-conserving design and start-stop technology employed in the drive train.

Upper and lower tools self-seat during clamping as the operator presses an icon on the machine’s touch-screen control. Tool positions are automatically calculated as part of the program, while flashing LEDs on the front of the upper beam instruct the operator where the tools need to be mounted to correspond with the 3D movements of the back gauge.

For further information www.bystronic.com