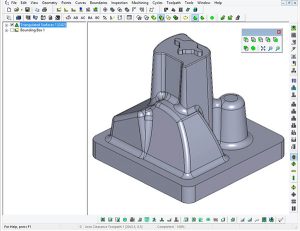

NCG CAM Solutions has released the latest version (v16.0) of its NCG CAM software.

This major release includes a number of new features, including: selected surface machining for waterline passes; combined passes for waterline and constant step-over; tangential extension for raster passes; five-axis flank machining; and many user-interface functions and enhancements.

Selected surface machining for waterline passes provides the ability to machine up to the surface edges without the need to create a boundary, in the same way as can be selected for shallow raster, radial and spiral strategies.

Retaining the waterline theme, a further new routine is available that allows the creation of waterline passes between the upper angle of 90° down to a specified lower angle. Constant step-over passes are then created to ‘fill in’ the shallow areas between the specified lower angle and 0°. Linking is a single operation from the top down, so that the linking order is a combination of waterline, constant step-over, waterline, and so on. This strategy will give a smoother finish because it allows the machining to be done in one operation, avoiding the problem of cutter wear.

In previous software versions, extending raster passes would allow the cutter to roll over the edge. Now, a new extension option creates passes which are extended at a tangent to the ends of the existing passes, and therefore extend the path beyond and away from the material being cut. The result of this functionality is that sharper edges are maintained. A horizontal pass extension has also been added.

With regard to five-axis strategies, flank machining is a new process that can be used typically for turbo-engine components, including turbine and impeller blades.

For further information www.ncgcam.com