Almost 78 years after Tenable Screw was founded by a Swiss watchmaker as a manufacturer of screws, the company has become one of the UK’s largest subcontract producers of turned parts.

With three manufacturing sites in Marlborough, Coventry and its headquarters in Wimbledon, Tenable has more than 250 machine tools that include 71 coil-fed Escomatics, 26 multi-spindle machines, 56 sliding-head turning centres and four fixed-head turning centres. The machines produce millions of components every month.

Committed to an ongoing culture of quality-assured engineering, Tenable Screw invests 10% of annual turnover in the latest technology to support its live base of over 250 customers. Part of this investment strategy has seen the arrival of a Tornos MultiSwiss 6X14.

The modern face of Tenable Screw sees the company manufacture everything from connector pins and sockets through to bolts, screws and much more for the electronics, instrumentation and control, automotive, aerospace, medical, defence, transport and telecommunications sectors in quantities that range from prototypes and small batch production up to runs of more than 100,000. With London property at a premium and the 45,000 sq ft Wimbledon headquarters packed with machine tools, the philosophy behind the MultiSwiss 6X14 purchase was to add flexibility and capacity to a business with limited floor space.

Commenting upon the arrival of the Tornos MultiSwiss 6X14, Tenable Screw commercial director Nigel Schlaefli says: “We initially acquired the MultiSwiss to alleviate capacity issues on our single-spindle sliding-head machines, while having the production capacity of multiple single-spindle machines in a floor area significantly smaller than five-to-six single-spindle machines. Although we initially used the MultiSwiss as a flexible centre that was supporting our single-spindle machines, like any subcontract manufacturer that has a fluid workflow, customer base and component types, the MultiSwiss is now dedicated to producing just one component family. Despite being restricted to a single family of parts, the productivity, precision, cost reduction and floor area benefits are evident.”

Just a few months after installing the MultiSwiss 6X14, Tenable Screw won a long-term automotive contract. The family of parts comprises stainless-steel pins that require numerous external turning processes, as well as knurling, drilling and parting off. The UK contract demands 1,500,000 parts every year, a quantity equal to 30,000 parts per week. Tenable Screw trialled the automotive part on one of its sliding-head turning centres and the cycle time was 1.5 parts per minute. In stark contrast, the MultiSwiss 6X14 was capable of producing 9 parts per minute – an output equal to six sliding-head turning centres.

“We calculated that we would have needed to run six single-spindle turning centres for 24 hours a day to meet the contract capacity level,” says Schlaefli. “In comparison, the MultiSwiss 6X14 hits the same output by just running for 17-18 hours a day. This means we can run the machine during a day shift, change tools and re-stock the barfeed at the end of the shift, and then run for an extra 8-9 hours unmanned.

As with all manufacturers with relentless quality standards, Tenable Screw has a dedicated quality control department and its production adheres to ISO9001. With regard to production, Tenable applies SPC and CPK procedures to its manufacturing processes. The CNC manager responsible for more than 60 CNC machine tools at Tenable Screw, Paul Kelley, says: “If we were producing this automotive part on six machines there would inevitably be a variation in CPK values between them. Although the part has an average tolerance band of ±20 µm, the MultiSwiss easily maintains a band of less than ±10 µm, and this improves our CPK and SPC values considerably.

“What we have also found is that each spindle on the MultiSwiss works independently, unlike conventional multi-spindle or CAM-auto machines. This allows us to change the spindle speeds for each spindle and operation, which in turn considerably improves surface finishes and contributes to extended tool life compared with other production machines.”

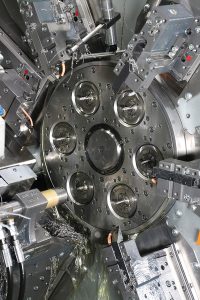

Contributing to both quality and tool life is the hydrostatic spindle technology integrated into the Tornos MultiSwiss 6X14.

“Over an extended period of time, roller bearing technology on machine tools will generate wear and this results in diminishing component quality,” explains Kelley. “However, the hydrostatic spindle technology on the Tornos eliminates wear; this means precision and consistency will not reduce. The hydrostatic spindle also eliminates vibration in the spindle head and this enhances component quality and surface finishes.”

Referring to the tool life on the machine, Kelley says: “The MultiSwiss will run for two days without any need for tool changes. Even then, we are only changing inserts as a precautionary measure. The only tool we change on a daily basis is the knurling tool. To put this in context, we are producing 18,000 stainless steel parts before we change inserts. The MultiSwiss is achieving at least double the tool life of the single-spindle machines.”

The MultiSwiss at Tenable Screw has demonstrated how it can lower floor-space requirements and reduce power consumption, tooling and general running costs compared with five or six single-spindle machine tools offering a similar production output.

Concluding upon the CNC control and ease-of-use characteristics of the MultiSwiss, Kelley says: “The MultiSwiss has 14 linear axes and seven C axes with up to 18 tool stations. Despite the number of axes and tool positions, the machine is significantly easier to program than single-spindle sliding-head machines. We apply G-code programming and determine the number of operations for each spindle. Combining these features with a well-lit and easy-to-access work envelope, the MultiSwiss is easier and faster to set-up than single-spindle machines.

“This ease-of-programming is certainly beneficial; but one equally important factor is the operator,” he adds. “There is a distinct lack of skilled CNC machine operators and programmers in the UK. Combining the ease-of-use characteristics with the facility to be as productive as six alternate machines, the MultiSwiss reduces the reliance and requirement for highly-skilled staff.”

For further information www.tornos.com