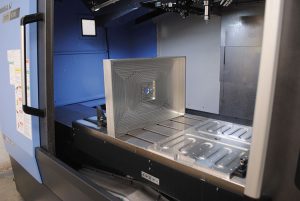

Ashbourne-based Thermoform Ltd, a manufacturer of bespoke vacuum and pressure formed plastic packaging solutions, has invested in a large-capacity Doosan three-axis VMC supplied by Mills CNC. The machine, a DNM 6700, was installed in the company’s toolroom facility in July 2017 and, just a couple of days following its delivery, was being put through its paces machining complex, precision prototype and production-ready aluminium mould tool parts.

These mould tools, when complete, are used by Thermoform to manufacture (at its adjacent 24/7 production facility) bespoke and often high-volume ‘thin-gauge’ plastic trays, clamshells, blisters and hinged containers for customers operating in the confectionary and bakery, meat, fruit and vegetable, pharmaceutical, toiletries, electronics, and DIY sectors.

Thermoform manufactures some 70 million plastic parts annually, and demand for its products, fuelled by organic growth and new contract wins, has grown exponentially in recent years. This upsurge in demand was putting pressure on the company’s toolroom: in particular the in-house CNC machining capacity and capabilities.

“The investment in the DNM 6700 enables us to machine large, as well as multiple smaller parts, in one set-up,” says managing director Matthew Perks. “As a consequence, cycle times have improved and bottlenecks have been eased considerably.”

Although still early days, Thermoform’s investment in a new Doosan DNM 6700 vertical machining centre is already paying dividends. A recent example of the power and performance of the DNM 6700 has seen a reduction in cycle time when machining a specific mould tool component from 8 hours to just 48 minutes.

For further information www.millscnc.co.uk