Open Mind Technologies exhibited its NC code-based HyperMill Virtual Machining Centre machine simulation for the first time at EMO in Hanover last month. In addition, live machining demonstrations using the strategies provided by the HyperMill Maxx Machining performance package were presented, while the company also offered a first glimpse of its upcoming HyperMill 2018.1.

With HyperMill Virtual Machining Centre, Open Mind has developed a solution that uses the NC code after the post-processor run as the basis for simulations. This ensures that virtual machine movements correspond exactly to the motion of the real machine.

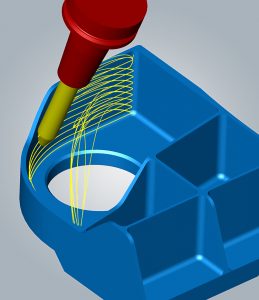

According to Open Mind, the HyperMill Maxx Machining performance package is able to help manufacturers achieve time savings of up to 90% during finishing and 75% during roughing. Visitors to the show were able to see live machining demonstrations and experience first-hand the potential for savings, especially with the five-axis tangent-plane machining strategy.

In HyperMill 2018.1, 2D contour milling based on the 3D model strategy will make it much easier to program vertical surfaces. The milling contour is generated automatically by selecting the perpendicular surfaces of the workpiece model.

For further information www.openmind-tech.com