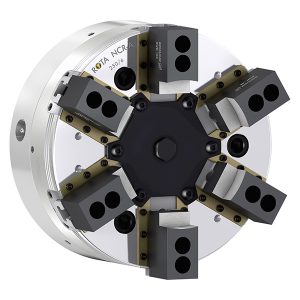

Schunk has expanded its product range with a sealed six-jaw pendulum compensation chuck for clamping deformation-sensitive workpieces.

The special seals located on the serrated jaw interface and pistons of the Schunk Rota NCR-A stop grease from being flushed out and prevent the clamping force from being gradually lost.

According to the company, precise chuck function is assured, even at low clamping forces. In addition, the seal prevents chips or dirt from ingress into the chuck body. This increases process reliability and lengthens maintenance intervals, translating into less frequent lubrication and cleaning of the lathe chuck, says Schunk.

The Rota NCR-A consists of a central chuck piston carrying three inner pendulums aligned at 120°. Each pendulum is connected to two base jaws. This configuration ensures workpiece centering between six contact points, which can be adjusted in pairs. As the clamping forces are directed towards the chuck centre, optimal centering is achieved without distortion of the workpiece.

The chuck adjusts to the workpiece with its oscillating jaws. In the case of ring-shaped workpieces, deformation is reduced by a factor of 10 compared with clamping using three-jaw chucks. Users can also clamp the pendulum of the Rota NCR-A in the centre position during the final processing stage or when clamping pre-turned surfaces so that all six jaws move concentrically. The clamping force between the first and second clamping can be adjusted by means of a pressure reduction at the hydraulic cylinder.

For further information www.gb.schunk.com