The latest generation of TruDisk lasers from Trumpf offers built-in intelligence to perform condition monitoring, predictive maintenance and trend analysis, all of which support the implementation of lasers in digital and connected manufacturing environments.

At the hub of the TruDisk beam source is the built-in control system known as CPX. This is the laser’s brain, where all of the condition data and process parameters are collected. During processing, sensors measure multiple parameters, including the actual laser output at microsecond intervals, all internal and external signal characteristics, the utilisation rate of the beam source, and the condition of additional components.

TruDisk lasers also incorporate a new feature that enhances the quality of data obtained from the readings. Known as ‘precision time protocol’, the feature synchronises the sensors and provides them with an identical time stamp.

The new lasers can be combined with Trumpf’s condition-based services (modular components of TruConnect, the company’s technology for connected manufacturing), which increase the availability and productivity of connected systems while identifying potential cost savings. With the customer’s prior approval, the services can be used to analyse data parameters, carry out algorithm-based trend analysis and take targeted measures to determine the risk of potential laser failure in advance.

Another improvement can be found in the new Trumpf laser diodes, which are energy efficient to help minimise running costs. Furthermore, Trumpf has equipped the latest TruDisk lasers with a pulse function that makes it possible to ramp the current of the pump diodes down to 0 A.

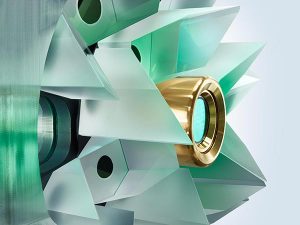

The new generation of TruDisk laser is available for laser output of between 3 and 5 kW, with fibre core diameters between 100 and 600 µm.

For further information www.trumpf.com