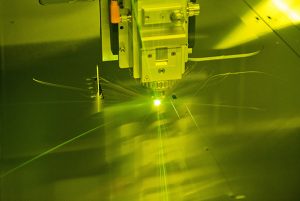

LVD has launched its Electra FL 3015 8 kW fibre laser cutting machine. Designed to cut a wide range of ferrous and non-ferrous materials as fast as the thermal process allows without dynamic compromise, the Electra 8 kW can maintain 2 G acceleration speed during operations. The Electra FL also features a new cutting head, new ‘smooth lead-in’ feature, advanced drive system and the latest generation of LVD’s Touch-L control.

Among the capabilities of the new cutting head is automated adjustment of focus position and focus diameter (zoom focus). Zoom focus control can improve piercing times, cutting speeds and cut performance in all material types and thicknesses, says LVD. This functionality can also increase throughput and reduce the need for operator intervention. The ability to change the focal point allows Electra to pierce 20 mm material in just 2 seconds.

The ‘smooth lead-in’ feature guarantees a much faster but stable lead-in after piercing thicker material (greater than 6 mm) with nitrogen. According to LVD, this capability results in an average 15% reduction in part-cutting times.

Two levels of automation are available: the FA-L load/unload system or CT-L compact tower. The latter offers loading, unloading and storage of raw materials and finished parts.

For further information www.lvdgroup.com