Innovative CAM technology can and should simplify the entire programming process. However, working with wire and water, instead of speeds and feeds, presents a challenge for CAM systems originally developed for conventional milling and turning applications. The concept of removing material with a cutter does not translate easily to the concept of eroding material with a thin wire.

Slicing through metal with an energised wire is a very efficient way to cut intricate shapes. These intricate part shapes have physical properties unique to the wire-cutting process, and include constant tapers, variable tapers, vertical land areas, sharp corners, radius corners, sharp corners that taper into radius corners, and more. A first step to simplifying the programming process is for a CAM system to recognise and retain knowledge of those unique properties so that wire programming can be automated.

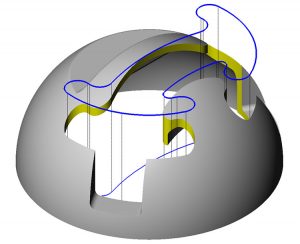

Esprit is a feature-based CAM system that automatically recognises machinable features that are specific to wire machining. Choices include die (pocket), punch (boss), hole, open profile, and even turning profile features for wire machines equipped with a rotary table.

An emphasis is placed on fast and easy creation of machinable features for wire EDM. Detailed properties about XY and UV profiles, workpiece height, tapers and corner styles are associated with the EDM features so that, regardless of the type or number of operations applied to the feature, the integrity of the underlying data remains the same. When EDM properties are embedded in the feature, the entire programming process is streamlined because most of the data needed for programming is coming from a single, reliable source.

For further information

www.espritcam.com