Banking and retail support services specialist, Camberley-based Cennox Plc,

is at the forefront in the battle against card skimming at cashpoints, developing components and systems that help banks stay one step ahead of the criminals. To maintain its lead, Cennox has an active R&D programme that requires numerous parts to be machined against relatively short lead-times. In addition, the company also has production parts to manufacture in order to back-up the service it provides to banks in repairing damaged cashpoints.

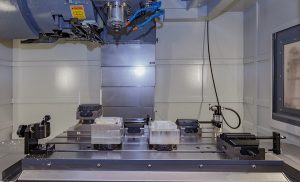

In the past, all of this machining work was outsourced, but as demand grew the cost and delays that this created was impacting on productivity, so the decision was taken to bring machining in-house. After investigating the market, Cennox chose Matchmaker CNC to supply the machine it required, as well as provide extra support in pulling together a tooling and CADCAM package (Sharp CAM). The selected machine was a Matchmaker VMC 1020 vertical machining centre with 1100 x

560 mm table that allows multiple set-ups to be in place at the

same time.

Typical savings against subcontracting these parts is running at around 75% per component. With initial batches running at 400-off, and ongoing at 20-30 off, this is a major saving.

“Considering that our starting point was of no machining experience whatsoever, we were probably a unique proposition for any machine tool company; we therefore had to place a lot of trust in Matchmaker,” says technical and operations support manager Iain Ferguson. “That trust was well placed as we now have a machining facility in which we are confident can produce anything that our design department comes up with.”

For further information

www.matchmakercnc.co.uk