Major enhancements to the 2018 R1 release of Edgecam from Vero Software include time saving updates to roughing cycles for milling, turning and mill-turn machining, and the prevention of unnecessary CAM regeneration. It is the latter update which is seen as being the most important for manufacturers. When a user makes an edit to an existing command, Edgecam 2018 R1 will not automatically regenerate the remaining instructions, so long as it does not affect the corresponding cycles with regard to factors such as coolant or speed.

Among the notable new items of functionality in Edgecam’s roughing cycle is ‘detect undercut stock’, which enhances the stock detection command by analysing previously undetected areas of stock. This option helps to avoid ‘fresh-air’ cutting, reducing machining time in some cases by up to half, says the company.

Furthermore, Edgecam’s Waveform Roughing Strategy has been updated to give machinists the ability to determine the radius size when using the helical approach option, simply by entering maximum and minimum values that aid the tool’s entry into the component.

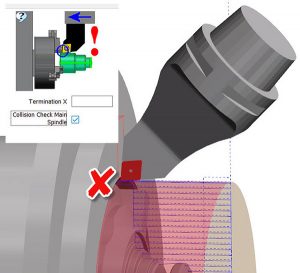

Automatic collision detection is among other additions to the rough-turning cycle. In previous versions of the software it was necessary to manually apply profile extensions to avoid collisions. This new function can also be used to produce safer toolpaths in the software’s ‘Strategy Manager’.

The profiling cycle used in both milling and turning now has two new items of functionality. A ‘spring cuts’ field has been added to the multi-passes tab, which means tool deflection can be removed where necessary, by adding extra neutral passes, known as spring passes. This feature will be used typically when machining hard materials, as repeating the profile pass can result in improved accuracy and surface finish.

For further information www.edgecam.com