German firm Rittal, a global manufacturer of control cabinets, is currently building the ‘factory of the future’ in Haiger. To this end, the company has placed a large order for a production line with Wemo worth “millions of euros”.

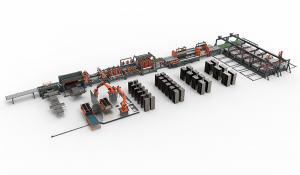

“The process begins with a stack of metal plates which our production line automatically feeds in, punches, corners-off and bends into a kit of parts that is then welded and painted by a third party to make a complete control cabinet,” explains Johan Lucas, commercial director at Wemo, which is represented in the UK by Press & Shear.

The fact that a leading German player such as Rittal – around €1bn in annual turnover plus factories on different continents – selected relatively compact Wemo in the Netherlands – “nearly 100 employees” – is significant because there are sufficient local and reputable machine manufacturers.

“As a builder and integrator of production lines for sheet metal working we deliver solutions for specific customer requirements which excel in terms of flexibility, speed and reliable technology, across their life cycle of up to 10-15 years,” says Lucas.

Rittal has in fact been a loyal and satisfied client of Wemo for many years.

“We have delivered lines for Rittal’s factories in America, among other places; and the next project is already in the pipeline,” says Lucas.

“As well as Rittal, we are very busy with other customers. For example, we have recently supplied complete lines, including assembly and welding, to Poland.”

For further information www.wemomachines.com