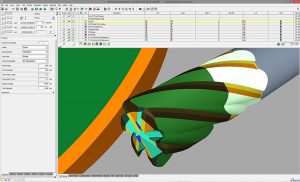

The latest version of the Walter Helitronic Tool Studio software for tool grinding now includes integrated functionality for the efficient and effective design, programming and simulation of PCD tool erosion.

Available from Walter Ewag, a member of the United Grinding Group, for all ‘two-in-one’ Walter Helitronic Power Diamond and Diamond Evolution tool-grinding and erosion machines, the new Tool Studio Erosion Wizard-enabled software is said to provide users with a quick and easy route to the selection and real-time simulation of PCD drill, mill and reamer production, incorporating both grinding and eroding operations.

After selecting tool size and geometry, then grinding wheel and electrode ‘package’, the system offers a simulation mode where parameters can be easily changed before tool production starts. Features also include automatic collision control, and geometry and parameter selection for individual teeth.

The new software complements similar Tool Studio functionality for the range of tooling that can be produced/reground on the Walter series of Helitronic tool grinders. This ‘what you see is what you grind’ system has, in effect, now been expanded and enhanced to a ‘what you can grind, you can also erode’ package.

Helitronic Diamond Evolution machines can grind and erode a range of carbide and PCD styles including shank, profile, circular and roll mills, multi-step tools and countersinks, as well as cutting and profile cutting plates. PCD tool programming routines include the erosion of PCD on tool diameters and the production of K-Land, variable spiral and ball-nose gash.

For further information

www.walter-machines.com